10 Mahlale a Theknoloji bakeng sa Letlapa la Seipone sa Acrylic

Ts'ebeliso ea liipone tsa acrylic e ntse e pharalla le ho feta, na ua tseba hore na mahlale a mantlha a ho etsa lishiti tsa seipone tsa acrylic ke afe?

DHUA e le moetsi ea hloahloa oa seipone sa polasetiki mona e thathamisa litheknoloji tse latelang tse 10 tsa ho etsa liipone tsa acrylic.

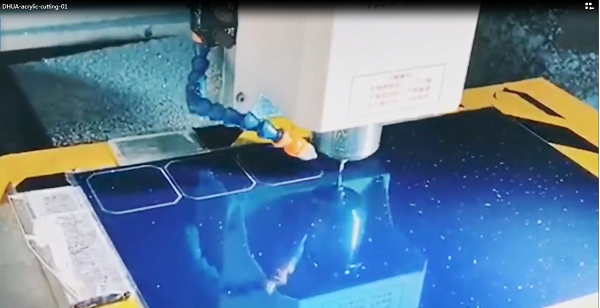

Saw cutting, router cutting process

Ha re fumana taelo ea tloaelo e nang le tlhokahalo e boletsoeng ea ho taka, re tla khaola maqephe a seipone sa acrylic ho latela litlhoko tsa litšoantšo tsa moreki.Re atisa ho bitsa mokhoa ona oa ho itšeha e le lisebelisoa tsa ho bula, sebelisa lisebelisoa kapa mechine e sehang, joalo ka thipa ea hook, hacksaw, saw saw, lisakha tsa lihlopha, tablesaw, jigsaw le router, ho khaola letlapa la seipone sa acrylic ho ea ka boholo bo boletsoeng le libopeho. tlhoko ea moreki.

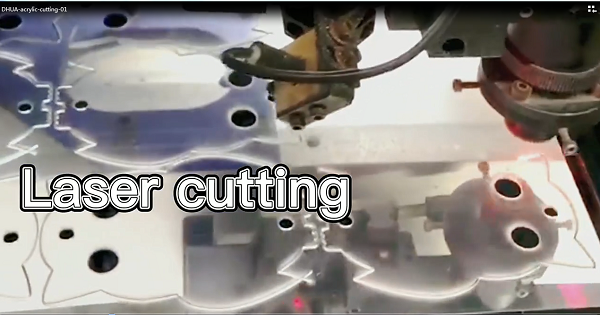

Mokhoa oa ho itšeha ka laser

Ha ho bapisoa le mochine o tloaelehileng oa ho itšeha, mochine oa ho itšeha oa laser o khetholloa haholo-holo ka tšebeliso ea laser ho itšeha, ho rua molemo ho boloka sebaka, ho boloka sebaka sa ho itšeha, le ho itšeha habonolo ho ea ka litšoantšo, mefuta eohle ea litšoantšo tsa ho itšeha, esita le setšoantšo se rarahaneng, ho itšeha ha ho na bothata. .

Mokhoa oa thermoforming

Acrylic e le thermoplastic e fana ka molemo oo re ka o etsang habonolo le ho o fa mefuta e mengata ea libopeho.Seo e se hlokang feela ke mocheso o itseng.Re bitsa ts'ebetso ena e le thermoforming, e tsejoang hape e le ho kobeha ho chesang.

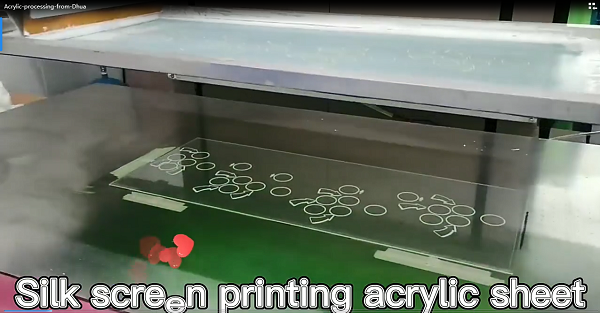

Mokhoa oa ho hatisa skrineng

Ho hatisa skrineng ke mokhoa oa ho fetisetsa enke holim'a substrate ea acrylic ka letlooeng, ho sebelisa squeegee / roller ho tlatsa li-apertures tse bulehileng.Khatiso ea skrine ka acrylic e sebelisitsoe haholo linthong tse entsoeng ka thepa ea acrylic.U ka hatisa litšoantšo tse mebala-bala, tsa boleng ba setšoantšo, li-logos le mongolo ka ho toba liipone tsa acrylic.

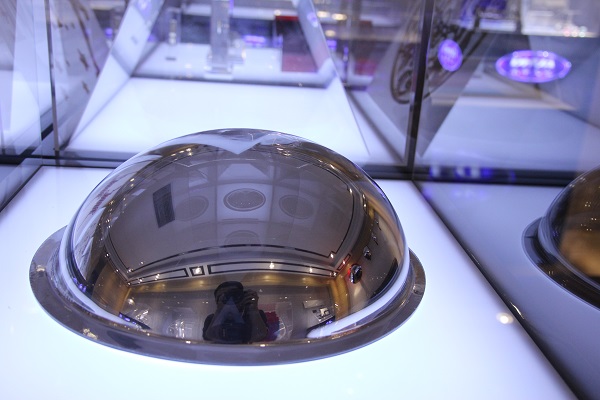

Fokaho bopa process

Ts'ebetso ea ho bopa ke mofuta oa ts'ebetso ea thermoforming, mokhoa ona haholo-holo ka ho foka.Ka mor'a phekolo ea mocheso, letlapa la acrylic le phunyeletsoa ka ntle ho hemisphere ka boholo bo hlokahalang , ebe o tsitsitse ho bōptjoa ka hlobo.

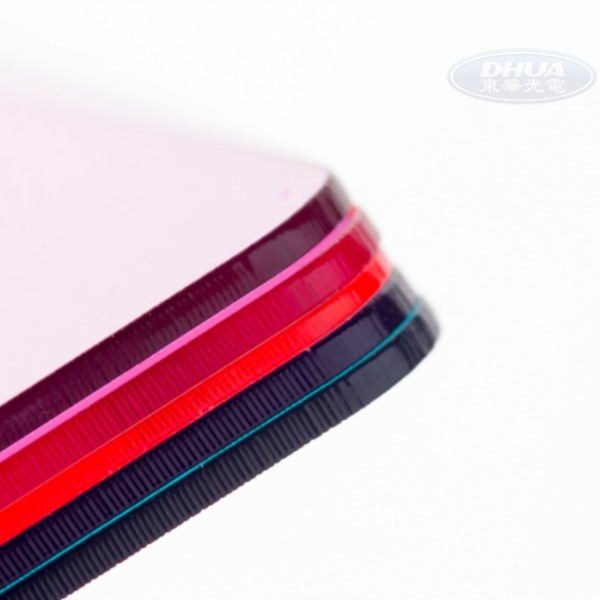

Gho qhitsa le ho bentšag tshebetso

Ho sila le ho bentsa ke ts'ebetso ka mor'a ho seha letlapa la seipone la acrylic kapa lakane ea acrylic.Ka mor'a ho itšeha, moeli oa seipone o ka 'na oa e-ba thata,' me tse ling li tla baka phello e mpe ea pono.Ka nako ena, re hloka ho sebelisa lisebelisoa tsa ho bentša ho bentša sebaka se potolohileng lakane ea acrylic, ho etsa hore e boreleli ntle le ho senya matsoho le ho etsa hore e shebahale hantle.

Mokhoa oa ho betla

Ho betla ke mokhoa o fokolang oa ho etsa / oa ho sebetsa moo sesebelisoa se senyang thepa ho tloha mosebetsing ho hlahisa ntho e lakatsehang ea sebopeho.Matsatsing ana, ts'ebetso ea caving hangata e etsoa ke router ea CNC e leng mochini oa ho itšeha o laoloang ke komporo o nang le sehahi se hokelletsoeng holim'a spindle e potolohang ho etsa ts'ebetso ea ho seha.

Mokhoa oa ho cheka

Acrylic drilling e bolela mokhoa oo u o sebelisang ho etsa masoba holim'a thepa ea acrylic ho sebeletsa merero e fapaneng.Ha u cheka thepa ea acrylic, u tla sebelisa sesebelisoa se tsejoang ka hore ke "drill bit", e leng eona e fapaneng ka boholo.Ho cheka Acrylic ho tloaelehile ho boholo ba lipontšo, lihlahisoa tse khabisitsoeng, lisebelisoa tsa foreimi joalo-joalo.

Ho roala ka vacuumtshebetso

Acrylic Mirror e entsoe ka letlapa la acrylic le sa khaotseng ebe le bōptjoa ho sebelisoa mokhoa oa vacuum metalizing, moo lakane e fanoang ka seipone e tšehelitsoeng ke tšireletso e tšoarellang.Ka mochini oa ho roala ka vacuum, re ka etsa maqephe a seipone a acrylic a mahlakoreng a mabeli, semi-transparent acrylic see thru seipone, lishiti tsa seipone tsa acrylic tse itšebetsang.

Mokhoa oa ho hlahloba

Ntle le tlhahlobo ea mantlha ea pono, le tlhahlobo ea bolelele, bophara, botenya, 'mala le phello ea seipone bakeng sa leqephe la seipone sa acrylic, ho na le tlhahlobo e eketsehileng ea litsebi ho netefatsa boleng ba lipampiri tsa rona tsa seipone tsa acrylic, joalo ka tlhahlobo ea boima, liteko tse sa sebetseng, tlhahlobo ea chromatic aberration. , teko ea phello, teko ea ho koba, teko ea matla a ho khomarela ect.

Nako ea poso: Nov-17-2022